In our previous blog, we talked about the best types of inks designed for especially screen printing. Did you notice why Water based ink is at the top of the list?

Table of Contents

ToggleBased on continuous research and client feedback, our today’s discussion is about what makes water based ink the best choice for screen printing and its difference from other ink types.

Overview

Water based ink as the name suggests has water as a main component in the ink for giving you a better screen printing experience. Screen printing has gained preference because it involves using quality inks other than standard types.

The absence of any plastic material in its composition makes it a reliable option for every printer. And guess what? Its use is not only limited to clothes. People are now using screen printing for home decor such as wallpaper or thin plastic sheets on walls.

These sheets featuring water-based inks give a bold look to your home. Let’s discuss how this ink acts on your surface and add glam to your printed items.

Most popular types of Ink

Speedball white water based ink:

If you are a beginner, this ink is a good choice for printing material. Other than coverage, it’s the cheapest ink to go. Moreover, it has no bad smell and is safe due to the lack of harsh material. This ink can work with both soft and hard materials like cardboard.

Ecotex Snow white:

This water based ink gives a clear understanding of eco-friendly ink types without plastic residues. It is tightly closed in a container, so don’t need to discharge. Despite being shiny, it gives a soft feel and uniform texture to clothes. You can mix it with other inks for unique prints.

Other screen printing inks That are similar to water based ink:

Some other ink types have water in their composition but have different features. Such as:

Discharge inks: They contain water as a solvent in composition but give different results. You need to add a catalyst to this ink to increase its performance. It also requires an air-tight dryer for curing at high temperatures. You need to wait for a long until it cures properly. Otherwise, you wouldn’t get satisfying results.

Acrylic ink: It is the second best option for screen printing projects. It has plastic polymer which is less harsh than PVC. It gives a sticky texture after curing and has some methods like common water based ink. Sometimes it requires the use of additives for the curing process.

Features Of Best water based ink include:

Composition: It has no plastic content in its composition. Water helps to dissolve colors quickly and give proper pigmentation to surface material. The garments can easily absorb the ink and reduce setting time.

Safe use: Although viscous, It gives a thin layer on printing sheets. These sheets can be used to wrap even food items. Printing with water based ink causes no hazards for humans and the environment.

Affordable: Using this ink in printing is an affordable choice. You don’t need to go beyond your budget. It is cheap to use for both home and commercial printing.

Large-scale use: There is no restriction to use water based ink for just printing paper and fabrics. You can print hard objects like wood, and boards too. Due to the large-scale applications, people prefer this ink over traditional ink.

Soft texture: When it dries out, it gives you a soft vibe. This softness lets it be used for making baby outfits, cushions, and bedsheets.

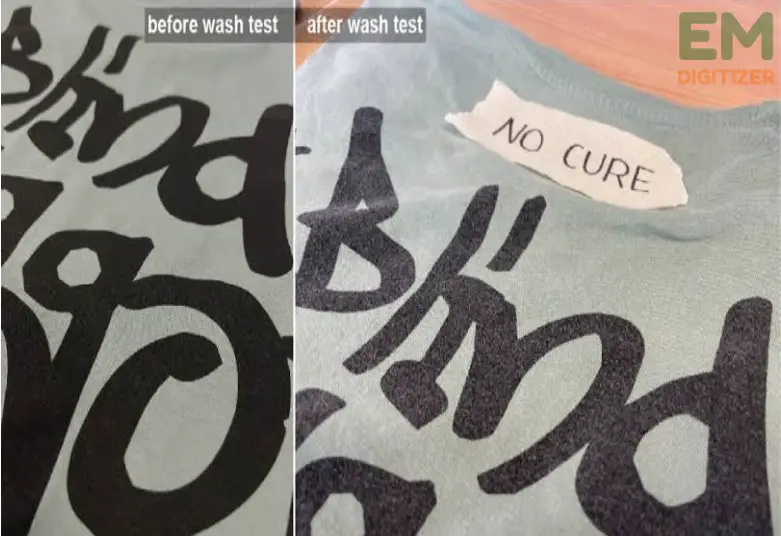

Long-term print: Prints made with water based ink usually won’t fade even after washing. These prints are also easy to clean with normal water.

You don’t need to purchase expensive detergents to wipe it off. After each wash, it appears as fresh as before. This is another reason, you will see it on top as excellent screen-printed ink.

Problem with water based ink:

Despite its large-scale use, it may not be a good option every time. There is no doubt having water makes it safe for use, but when exposed, it starts evaporating. And It leads to the mesh blockage.

Solution:

It is a good habit to clear the surface after applying this ink. Because if you walk away leaving the surface open, it starts drying. It will destroy your design without getting complete. So try to use it in humid areas.

Use of blow dryer:

Water based ink also required the use of a quick dryer that forced the airflow. This dryer lets the warm air blow out of it to evaporate water to cure it quickly.

What if you don’t have an expensive forced air dryer? The good part is that you can also use your casual dryer with any curing method.

How to increase the efficiency of water based ink:

For a more creative touch, you can add extra color and additives to any water based ink. If you are looking for 3D prints, go for specialty ink. It usually has two shades, silver and gold to make your print puffy.

Benefits:

Recently, printers have expanded the use of water based ink over materials. Now it is not only confined to the apparel industry.

- You can apply this ink over any hardwood or cardboard to make something unique and functional.

- Due to Its safe composition and durability, retailers are using them in printing papers and sheets for storing and packaging purposes.

- Widely used by popular brands for textured logos and letters such as the Nike brand.

- With the addition of specialty ink, one can decorate the room with water-based ink-featured wallpaper and covers.

- Different cotton, linen even polyester fabrics can soak up these inks. They look like original fabric rather than just print.

- These prints leave a strong impression on your clients.

- These inks are highly breathable. So you can carry printed shirts even on hot days like sports shirts.

Conclusion

Hopefully, this guide has cleared all your questions about water based ink either positive or doubtful. After keen analysis, I have figured out what makes it good for screen printing. I again repeat some of the few points. When you go out to get the best ink, remember to check its coverage, usage, application, and curing method. Most importantly, keep in mind your printing budget. Because sometimes the cheapest products may give unexpected results.

For adding extra colors to your prints, try using additives that help mix with ink. They give more color and 3D texture to the prints. Most popular printing brands are using this technique such as Nike shirts and Adidas etc.

Curing water-based ink is a time-consuming process. You can cure this ink with your normal hair dryer without forced air or a blow dryer. It works on a similar principle. It pushed off warm air to lessen the setting time of ink. So, it is advisable to start printing in less moisture areas.

If you have any questions leave the comments or you can visit our social channels for more updates regularly. We provide embroidery digitizing services if you need digitizing services feel free to contact us or email us.