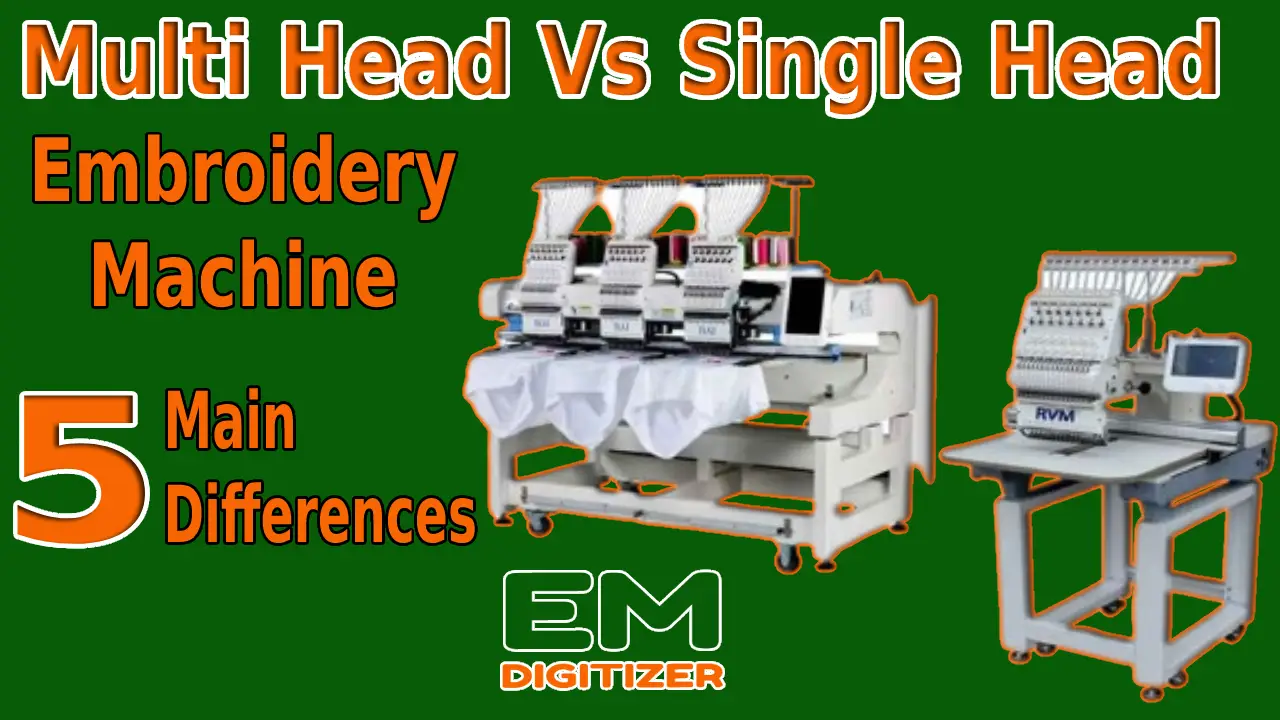

Multi Head Vs Single Head Embroidery Machine – 5 Main Differences

Embroidery has been an art form that has been practiced for centuries. From hand embroidery to machine embroidery, it has evolved into a significant industry that has transformed the way we create designs and patterns on fabrics.

With the advancement of technology, embroidery machines have come a long way from manual stitching to automated machines. One of the key advancements in the embroidery industry is the introduction of multi-head embroidery machines.

In this blog, we will compare multi-head embroidery machines with single-head embroidery machines to help you choose the right machine for your needs.

If you are looking for embroidery digitizing services, EMDigitizer is one of the best embroidery digitizing companies. Providing all types of embroidery digitizing Services. I recommend you try digitizing services.

Order NowGet Free QuoteTable of Contents

Single Head Embroidery Machine

A single head embroidery machine is a type of embroidery machine that typically has one sewing head and is designed to create intricate and detailed embroidery designs on a variety of fabrics and materials.

It is ideal for small to medium-sized businesses, as well as for home-based embroidery enthusiasts. They can also be connected to a computer to allow for custom designs to be imported and embroidered.

Single head embroidery machines usually come equipped with a range of features, such as automatic thread trimming, multiple hoop sizes, and a range of built-in embroidery designs.

These machines are commonly used in a range of industries such as fashion, textiles, and promotional products, and are also popular among hobbyists who enjoy creating custom embroidery designs for personal use or to give as embroidered gifts.

Check out these ideas for giving embroidered gifts to friends and family in this blog.

Single head embroidery machines are available from a variety of manufacturers, with different price points and features, and sets to suit different budgets.

Pros

- Single head embroidery machines are ideal for small-scale embroidery projects, making them perfect for customization and personalized embroidery work.

- Single head embroidery machines are easy to operate, and they do not require extensive training to use.

- Compared to multi-head, single head embroidery machines are significantly cheaper, making them ideal for startups or small home-based businesses with limited budgets.

- Single head embroidery machines are compact and take up less space compared to their multi-head counterparts.

Check out the article to get a step-by-step guide on how to start your own small home-based embroidery business.

Cons

- Single head embroidery machines are not designed for mass production.

- Single head embroidery machines are time-consuming as embroidering a single design can take several hours, making them unsuitable for rush orders.

- Single head embroidery machines require an operator to load and unload fabric, change thread colors, and perform maintenance.

- The single head embroidery machine has only one head, and it requires constant supervision and manual intervention, which can be time-consuming and limit the operator’s ability to work on other tasks simultaneously.

Multi-Head Embroidery Machine

A multi-head embroidery machine is a specialized sewing machine that is used for creating intricate designs and patterns on fabric using embroidery techniques.

Here’s a selection of the top embroidery fabrics to help you choose the perfect match to complete your embroidery project.

Unlike a single head embroidery machine, a multi-head embroidery machine has multiple needles and heads, allowing it to work on several pieces of fabric at the same time.

If you want to get knowledge about What Is Mass Production of Embroidery, then you can visit: Mass Production of Embroidery

The number of heads on a multi-head embroidery machine can vary depending on the model, with some machines having as few as two heads, while others can have as many as 20 or more.

Each head can have multiple needles, typically between six and 15, which allows for the simultaneous stitching of multiple colors and designs increasing efficiency and productivity.

Multi-head embroidery machines are commonly used in industrial and commercial settings, such as in the production of embroidered logos or designs on clothing, hats, bags, and other textile products.

Why Should You Invest In A Multi-Head Embroidery Machine?

A multi-head embroidery machine is often referred to as a commercial-grade embroidery machine because it is specifically designed for businesses that require high-volume embroidery production.

These machines are built with durable and high-quality components to withstand the demands of daily commercial use and produce high-quality embroidery work quickly, which is crucial in a commercial setting where time is money.

Additionally, multi-head embroidery machines typically have advanced features such as automatic thread trimming, color changes, and pattern sequencing that make them ideal for producing large and complex designs.

All of these features and qualities make multi-head embroidery machines a valuable investment for businesses looking to streamline their embroidery production and improve their overall efficiency and profitability.

Check out the list of the best commercial embroidery machines on the market that can help your business grow.

Five Key Differences

Multi-head embroidery machines offer several advantages over traditional single head embroidery machines, including:

1- Execute More orders In A Reasonable Timeframe

Multi-head embroidery machines are designed to handle several embroidered designs at the same time in a fraction of the time that a single head embroidery machine would take to generate the same number of designs.

This increased productivity allows businesses to take on larger orders and fulfill them more quickly. They are equipped with features like:

- Automatic thread trimming

- Automatic color changes

- An automatic tension control helps to reduce the time and effort required to produce high-quality embroidery.

Examples

- If a customer places an order for 50 embroidered hats, a single head embroidery machine would require the operator to embroider each hat one at a time, resulting in a significant amount of time spent on the order.

- However, a multi-head embroidery machine with 6 or 12 heads can embroider all 50 hats at once or in just a few setups, drastically reducing the time it takes to complete the order.

2- Cut Labor And Expenses

When using a single head embroidery machine, the operator has to re-thread the machine and change the embroidery design for each item they embroider.

With a multi-head machine, each head can be set up to embroider a different design, so the operator doesn’t need to change the setup, this can reduce the time it takes to set up the machine which can save on labor costs.

Because a multi-head embroidery machine can produce more embroidered items in less time, the cost per item can be lower.

And the cost of the operator’s time is spread across more items, making each item less expensive to produce.

Examples

- Instead of having to embroider 10 garments one by one, a multi-head machine can complete all 10 at the same time, resulting in faster production times and reduced labor costs.

- If a single head embroidery machine can produce 20 hats per hour, and a 6-head machine can produce 120 hats per hour, the cost per hat will be lower on the multi-head machine.

If you are seeking the best embroidery machine to embroider caps and shirts, here are some helpful suggestions.

3- Professional Quality Work

Multihead embroidery machines provide high-quality work by combining precision, speed, consistency, and versatility in their embroidery capabilities.

- Multihead embroidery machines use computer-controlled technology to ensure that every stitch is placed with precision and accuracy as even the slightest variation in stitching can affect the overall quality of the final product.

- Multihead embroidery machines are equipped with color sensors to ensure that the finished product matches the design exactly, which is particularly important when working with branded or custom designs.

- Its automatic thread tension systems ensure the same amount of tension is applied to each needle, resulting in consistent stitching throughout the design for maintaining the quality and appearance of the embroidery work.

Here is a complete guide on The Power Of Stitch Vision Quilting Laser

Examples

Here are a few examples of how multi-head embroidery machines can produce high-quality work:

- Multihead embroidery machines can handle a wide variety of fabrics, threads, and designs and this versatility allows you to create high-quality designs on a range of materials, from t-shirts to jackets, hats, and more.

- Used by businesses to create high-quality embroidered logos on uniforms, hats, and other products.

- The precision of the stitching and the ability to use a wide range of thread colors ensure that the logo looks professional and eye-catching.

- Multihead embroidery machines can also produce more high-quality embroidered patches than single head embroidery machines, which are commonly used for uniforms, backpacks, and other items.

If you want to produce your own embroidered patches, here is a list of the supplies you’ll need for embroidery patches and tips on how to utilize them effectively.

4- Increased Processing Time For Bulk Orders

The increased productivity and efficiency of multi-head embroidery machines allow businesses to accept larger orders and meet tight deadlines.

With the ability to produce multiple designs simultaneously, businesses can take on more significant orders without compromising turnaround times and quality.

Examples

1) Let’s say a customer requests 100 embroidered hats with a design that is relatively intricate and has several colors. If a single head embroidery machine were used, it would take a significant amount of time to embroider each hat individually.

However, with a multi-head embroidery machine, the hats can be embroidered simultaneously, with each needle working on a different hat at the same time, and this allows for the completion of larger orders in a shorter amount of time.

2) Another example would be a large-scale corporate order for embroidered polo shirts. With a multi-head embroidery machine, each shirt can be embroidered with the company’s logo in a matter of minutes.

Without a multi-head embroidery machine, it would take significantly longer to embroider each shirt individually, which would make completing the order on time more difficult.

5- High Production volume

The use of multi-head embroidery machines has had a significant impact on the embroidery industry by increasing production volume and reducing costs.

For example, if a traditional embroidery machine can produce 50 pieces in a day, a multi-head embroidery machine with six heads can produce up to 300 pieces in a day.

This has allowed businesses to produce more designs in a shorter amount of time, without compromising on quality, which has ultimately led to increased profits.

Examples

1) Let’s consider a scenario where a traditional embroidery machine takes 10 minutes to embroider a design on a single garment.

E.g, If you need to embroider the same design on 100 garments, it would take 1000 minutes or approximately 16.5 hours to complete. In contrast, a multi-head embroidery machine with eight heads can complete the same job in just over an hour.

2) Another example would be for large orders, such as uniforms for a sports team or staff at a restaurant. A multi-head embroidery machine can quickly embroider identical designs on multiple garments, making it possible to fulfill the order within a shorter time frame.

This not only satisfies the customers’ needs but allows businesses to offer more customization options to their customers, which can lead to increased sales.

This post will give you the best suggestions for increasing sales in the embroidery business.

Final Thoughts

When deciding which embroidery machine to choose, it is important to consider your business needs and production volume.

- If you are a small business or hobbyist, a single head embroidery machine may be a great option for you.

- If you require a high production volume, a multi-head embroidery machine may be a better fit.

Conclusion

Both single head embroidery machines and multi-head machines have their advantages and disadvantages. The choice between the two depends on your business’s needs, budget, and the type of embroidery projects you plan to undertake.

If you are unsure about which machine to choose, speak to an embroidery machine supplier or a consultant who can help you make the right decision.

A single-head embroidery machine has only one embroidery head, which limits the amount of embroidery that can be done at one time. A multi-head embroidery machine, on the other hand, has multiple heads, allowing for more efficient and productive embroidery.

The main drawback of a multi-head embroidery machine is its cost, as it is typically more expensive than a single-head embroidery machine. Additionally, it may require more space and maintenance than a single-head machine.

When choosing between a single-head and multi-head embroidery machine, you should consider factors such as the volume of embroidery you need to produce, your budget, the space you have available, and your maintenance capabilities.

If you need to produce a high volume of embroidery and have the budget and space for a multi-head machine, it may be the better choice. However, if you have a smaller budget or limited space, a single-head machine may be more suitable.

If you have any questions leave the comments or you can visit our social channels for more updates regularly. We provide embroidery digitizing services if you need digitizing services feel free to contact us or email us.